.

.September

29, 2004

.

This Week:

-

Third Opel World Premiere in Paris: Astra High Performance Concept

-

A Ford Fiesta Hybrid Concept-Car Using the Valeo StARS Technology

-

Hyundai Sonata Premieres at Mondial de l'Automobile in Paris

© 1998

- 2004 Copyright &

Disclaimer

Automotive Intelligence,

www.autointell.com

All Rights Reserved .

For questions please contact

editor@autointell.net

.

The 2005 Stampede Begins - New Ford Mustang

|

|

FLAT ROCK, Mich. - AutoAlliance International today opened its gate for the stampede of the most anticipated car in America, the all-new 2005 Ford Mustang.

With retail orders running 60 percent higher than expected, Jim Padilla, chief operating officer, Ford Motor Company, congratulated the 3,600 AAI employees on building the new model of America's favorite car with great precision and pride.

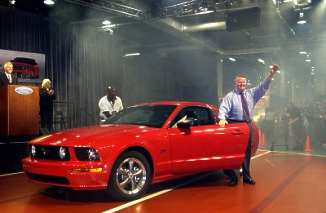

Ford Mustang launch with Jim Padilla

Photos: Ford

"America, your car is ready," Padilla told the cheering crowd. "Mustang is the exclamation point of Ford's product onslaught. There is no other car like it. And here at AutoAlliance, the 2005 model has found a great home. This plant, with its all-new flexible system, stands as a world-class plant in advanced automotive manufacturing systems and processes."

Ford invested nearly $700 million in AAI's flexible manufacturing system, which makes the plant capable of building up to six different models on two vehicle platforms.

This investment includes a new body shop with 380 robots and flexible tooling as well as an upgraded stamping operation with 38 new die sets capable of stamping 52 critical body parts. Major upgrades to the final assembly area include programmable platforms, or skillets, that hold the body on a scissor lift and adjust to the operator's height for improved ergonomics.

"The new technology in our plant means we can make a great car even greater," said Phil Spender, AAI president. "With quality a top priority, the 2005 Mustang is built with extreme precision and attention to detail on an all-new platform."

The precision build of the Mustang is ensured by various dimensional control systems throughout the manufacturing process. Among them:

Dimensional Control Center: Data on the critical dimensional points of body components - such as engines, instrument panels, doors and suspension systems - are collected and studied regularly by quality engineers.

In-line laser dimensional control and a web-based data management system: These robot-mounted lasers measure critical body dimensions on the underbody line and the body framing line, to prevent variances in the build process.

Padilla and Spender hosted a plant celebration for employees, community guests, union leaders, dealers, state and federal government officials and media.

To prepare for production of the 2005 Mustang, AAI invested $30 million to train employees in highly skilled advanced manufacturing technologies and processes. The technical training will be open to local high school students through future vocational education programs.

(Sept. 27, 2004)

| .

Homepage News Companies Management Publications Events Guestbook Search . |