Automotive Intelligence - the web for automotive professionals and car enthusiasts

September 16, 2010

This Week:

-

High Performance ST Tops New Ford Focus Lineup for Paris Motor Show Launch

-

Porsche Adds Expressive and Performance-Oriented 911 GTS Model

-

Automotive consortium showcases Flywheel Hybrid System for Premium Vehicles

-

The Fiat Brand Arrives into the U.S. with the Iconic Fiat Cinquecento

-

Chrysler Brand Releases Information Regarding New 2011 Mid-sized Sedan, the Chrysler 200

-

High-performance sports coupe Audi TT RS is coming to America

-

BMW M6 Coupé and BMW M6 Convertible reach the end of their career

-

The Mercedes-Benz A-Class E-CELL - The family electric car for urban areas

© 1998 - 2010

Copyright &

Disclaimer

Automotive Intelligence,

www.autointell.com

All Rights Reserved .

For questions please contact

editor@autointell.net

|

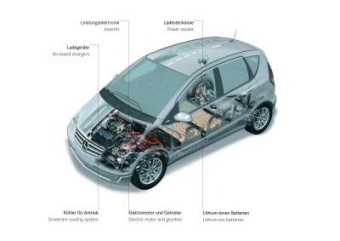

The Mercedes-Benz A-Class E-CELL - The family electric car for urban areas

Stuttgart - Following the B‑Class F‑CELL fuel-cell car, Mercedes‑Benz now introduces the new A-Class E-CELL as its second electric car built in series-production conditions. The five-seater with battery-powered electric drive meets all the requirements for a family car for everyday use. It is based on the five-door version of the current A‑Class, and features a generously dimensioned interior and luggage compartment for maximum versatility. No compromises have been necessary in terms of space and variability, with compact storage batteries that are located extremely well-protected and in a space-saving way in the vehicle underbase. |

|

|

|

The car’s two high-efficiency lithium-ion batteries provide a range of over 200 km (NEDC). The car is powered by a quiet, locally emission-free electric drive with peak output of 70 kW (95 hp), developing a high torque of 290 Nm. A total production run of 500 A‑Class E‑CELL cars will be built at Rastatt from autumn 2010. The vehicles will be leased to selected customers in several European countries, including Germany, France and the Netherlands. |

|

Five doors, five seats, the same luggage compartment volume as in the internal combustion engine A‑Class (435 to 1370 litres), a 350‑kilogram payload measured as per the relevant EC directive and high variability of the interior and luggage compartment: this is what makes the new A-Class E-CELL a family car for everyday use. The sophisticated sandwich structure provides both an extremely comfortable in-car environment and maximum protection for passengers and components in the event of a collision.

“Over our almost 125-year history, we have accumulated extensive experience and knowhow in the area of electric vehicles, including both battery and fuel-cell. This knowhow has already provided the basis for getting two electric cars for everyday use onto the road: the smart fortwo electric drive, and the B‑Class F‑CELL. The story now continues with our third electric car, the A‑Class E‑CELL., whose start of production is scheduled for autumn this year. The new car is a battery-driven electric Mercedes that enlarges our portfolio and offers our customers the kind of driving pleasure, comfort and safety that they have come to expect”, says Dr Thomas Weber, the Daimler AG Board of Management member responsible for Group Research and Development Mercedes-Benz Cars. Driving pleasure with zero emissions Along with exemplary safety, optimum comfort and a high level of suitability for daily use, the A‑Class E‑CELL also offers other strengths not always to be found in contemporary electric cars: agility and driving pleasure. The features are based on a low centre of gravity, partly the result of the installation of the batteries under the passenger compartment, in the “sandwich” structure of the vehicle floor. This gives the car excellent road-holding and sprightly handling characteristics – qualities that clearly set the A‑Class E‑CELL apart from other electric cars, which often have heavy and bulky storage batteries located in the boot or by the rear seat. Another benefit from this installation location is the provision of best-possible protection against the intrusion of structural components in the event of a head-on collision or impact from the rear. This is because the batteries are located outside the vehicle body’s deformation zones. The high-stability characteristics of the sandwich structure of the floor also provide outstanding protection for both battery and passengers in a lateral collision scenario. High-performance electric drive with long range The electric drive of the A‑Class E‑CELL is a permanent-field synchronous unit developing a peak output of 70 kW (95 hp), a continuous power rating of 50 kW (68 hp) and a high maximum torque of 290 Nm, as expected for an electric drive, available right from the first revolution. This makes the A‑Class E‑CELL an outstandingly assured and dynamic performer on the road, taking just 5.5 seconds to accelerate from zero to 60 km/h. A kick-down function is used to deliver maximum acceleration, according to the current charge level and battery temperature. Maximum speed is electronically set at 150 km/h. The energy storage units are two high-performance lithium-ion batteries based on high-voltage technology. The advantages of lithium-ion batteries include their compact dimensions and significantly higher efficiency in comparison with nickel-metal-hydride (NiMH) batteries. They offer 30 percent more energy density than NiMH technology, and 50 percent more power density. Other benefits include high charging efficiency and a long service life. The combined energy capacity of the two lithium-ion batteries is a total of 36 kWh. With fully charged batteries, the A‑Class E‑CELL has a range of over 200 kilometres (NEDC). Efficient battery cooling system A special thermomanagement system keeps the high-voltage batteries cooled to within an optimum temperature window. The cooling system is based on a low-temperature cooling circuit. Fluid cooling with a water-glycol mixture ensures a stable operating temperature supporting the high degree of efficiency and the longevity of the energy storage. In very high ambient temperature conditions, the battery cooling system is boosted with the coolant circuit of the air-conditioning system. The electrical drive system and two on-board chargers are cooled with a high-temperature cooling circuit. This circuit keeps the units working at optimum operating temperatures, with maximum power delivery from the drive system. The car’s power electronics supply the 12-volt vehicle electrical system via a DC/DC converter with electric current from the high-voltage system. The electronics system also controls other functions such as the heating and air-conditioning systems in order to minimise the load placed on the battery for this purpose. Flexible charging options The batteries of the A‑Class E‑CELL can be either replenished at public charging points or plugged into an ordinary household power socket. A range of charging options are available, including single-phase 230-volt sockets, three-phase sockets in a household wall-box, and public recharging points. Using a single-phase 230-volt network, it takes around eight hours’ charging time to accumulate the energy required for a range of 100 km (NEDC). This time is reduced to just three hours in the case of charging from a wall-box or at a roadside recharging point. Daimler and a number of other European automakers and energy utilities have agreed on standardised charging plugs and sockets, with an ultimate aim of worldwide standardisation. This makes the technology more customer-friendly, and is seen as a key prerequisite for the rapid spread of electric mobility. Intelligent charging management Like the smart fortwo electric drive in its category, the A‑Class E‑CELL is the world’s first vehicle in its class to be fitted with an intelligent charging management system based on “SmartCharge Communication”. Via the vehicle electronics system, all relevant information – such as the electricity supply contract identification data – is exchanged with the charging point. Benefits include a convenient, simple and totally reliable billing system. Other intelligent features of the car include pre-start climate control. While the A‑Class E‑CELL batteries are being charged at home or at a roadside charging point, the interior can be pre-heated or cooled to a temperature set by the driver. Another function enables the driver to monitor charging progress and therefore the present range available, via the internet or a smartphone, for example. The A‑Class E‑CELL electronics also provide for proactive control of the charging operation. So if the electric car is parked for a long period, recharging can be set to take place at times when electricity is cheaper, for example during the night. The intelligent interface in the A‑Class E‑CELL provides a range of billing, control and monitoring functions, making electric mobility convenient and safe, and therefore very customer-friendly. The vehicle is automatically immobilised on connection of the charging cable to the socket, preventing any possibility of driving off by mistake while charging is in progress. This makes the recharging operation even safer and more convenient for the user.

Everything under control” when out on the road Another detail specific to the system is a display of the currently available drive power. Meanwhile, the rev counter normally to be found on the instrument panel is replaced with an indicator showing the instantaneous drive power demand or recovery power. Green, white and red-coloured segments show whether the drive system is currently operating in charge, economy or boost mode. Modular system for electric cars In line with the strategy used for hybrid development, Mercedes engineers have also developed a modular system for electric vehicles with battery and fuel-cell. The benefits include the efficient use of shared parts in all the brand’s electric vehicles. All the key components of electric cars are appropriate for a modular approach – for example, the electric drive of the A‑Class E‑CELL is also used in the B‑Class F‑CELL. Both energy storage units in the electric A‑Class are the same as the battery in the smart fortwo electric drive. Photos: M-B (Sept. 14, 2010)

|

|