.

March

31, 2005

.

This Week:

-

GT500 Reborn As A Modern Thoroughbred: Shelby, SVT Create Most Powerful Mustang Ever

-

Dodge in Hot Pursuit of Police Car Market with HEMI®-powered 2006 Dodge Charger

-

Scion Unveils All-New t2B Concept Vehicle at 2005 New York Auto Show

-

Donald Trump To Be The First Cadillac DTS Executive Limousine Customer

-

Jaguar To Introduce New 2006 'Super V8 Portfolio' Luxury Sedan At The New York Auto Show

-

Learning from Nature: BMW in the German Pavilion at EXPO 2005 in Japan

-

DaimlerChrysler Commits Over $70 Million to Fuel Cell Development in the U.S.

© 1998

- 2005 Copyright &

Disclaimer

Automotive Intelligence,

www.autointell.com

All Rights Reserved .

For questions please contact

editor@autointell.net

.

Learning from Nature: BMW in the German Pavilion at EXPO 2005 in Japan

The motto of the World Exhibition: "Nature's Wisdom" - Natural models providing solutions as role models for technical innovations

Photo: BMW

|

MUNICH, Germany and AICHI, Japan - Some 120 countries and organizations will be focusing on nature and the associated opportunities for technical developments at this year's world exhibition being held in Aichi, Japan. The EXPO - open from 25 March to 25 September 2005 - will encourage visitors to understand the principles of nature through modern perspectives. It will also persuade people to integrate them within their daily lives and promote harmonious coexistence between nature and technology. |

|

A trip through "Bionis"

The subject of bionics is presented to visitors as they pass through the German Pavilion. The term "bionics" is an artificial word put together from "biology" and "technology". It advocates exploiting "Nature's Wisdom", in order to develop exciting technical concepts and solutions through the abstraction of natural forms and the underlying mechanisms of action.

BMW is the only automobile manufacturer exhibiting in the German Pavilion and the company profiles research results inspired by bionics. Interactive exhibits allow visitors to experience at close hand where and how natural principles generated initiatives that led to solutions in automotive technology. It also demonstrates how this process will continue.

"As the process of evolution progressed, plants and animals were able to adapt continuously to the environment they happened to exist in. This allowed them to develop optimum solutions as they interacted with nature. Many of the results are superior to the latest technical solutions because they achieve greater efficiency with much less material and expenditure of energy. However, the best ideas for solutions to engineering problems are not usually based purely on the application of concepts that are absolutely equivalent to natural principles. Our modern-day inventions are usually derived from optimized adaptation of these principles to meet the challenges posed by engineering. BMW seeks to exploit the opportunities available in this area of research. We are looking for ways to further enhance fuel economy, safety and dynamic performance of the vehicles we manufacture," emphasizes Prof. Burkhard Göschel, Member of the Executive Board of BMW AG.

A cross-section through the cockpit in the new BMW 3 Series shows visitors to the exhibition in Aichi how a natural principle can be applied innovatively in practice. Other exhibits also provide further insights into this process of invention. Lightweight construction was a top priority when selecting the material for the instrument panel. The material had to absorb energy and also have ergonomic qualities. Engineers at the Landshut Innovation and Technology Centre (LITZ) carrying out research for the BMW Group used nature as a model to develop a completely new process engineering system, which they called injection-moulding integral foaming. This process involves the addition of a foaming agent to the plastic melt. When the foaming agent is heated, it liberates gas in the same way as baking powder in cakes. When the tool mould has been filled and the surfaces of the component have solidified, the mould is opened by a precisely defined distance. The effect is to reduce the pressure in the fluid interior of the component, allowing the gas to expand the plastic melt. The result: 20 percent less weight.

The specialists in lightweight construction drew on mammalian bone structure when they were developing the process. The ingenious design used in nature means that solid, load-bearing material is mainly used at points that are subject to high stresses. A structure full of cavities is easily able to withstand the loads exerted in other areas. The result: efficient structures with minimum use of material.

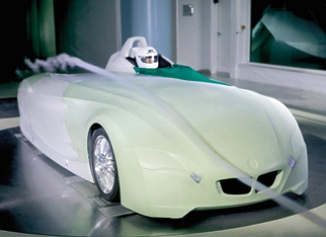

Other exhibits, such as the BMW record vehicle H2R powered by a hydrogen combustion engine, illustrate the latest status of research into technical innovations. Nature was also the model for this development.

(March 24, 2005)

| .

Homepage News Companies Management Publications Events Guestbook Search . |